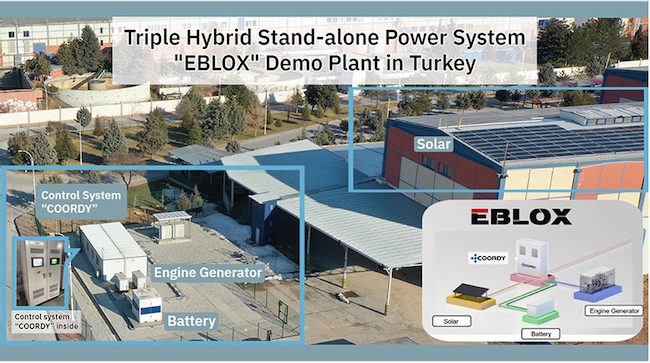

Smart, Hybrid, Distributed: MHI Completes EBLOX Demonstration Plant in Turkey

Construction of a power plant in Turkey that will demonstrate a stand-alone “triple hybrid” system featuring renewable power sources, a reciprocating engine generator, and a battery has been completed.

Mitsubishi Heavy Industries (MHI) Group subsidiary Mitsubishi Heavy Industries Engine & Turbocharger, Ltd. (MHIET) and Calik Enerji Sanayi ve Ticaret A.S., a subsidiary of Turkish energy infrastructure firm Calik Holding, on March 23 said their first “EBLOX” system is readying for operation at the Calik Denim factory in Malatya, Turkey.

The Matlaya EBLOX system, which is designed to supply isolated microgrids, consists of a 120-kW solar power system, a 150-kW/167-kWh storage battery, two 34-kW gensets, a “dummy” load device of 300-kW, and a “COORDY” control system, the partners said.

The project stems from a 2019 memorandum of understanding to promote EBLOX as a distributed power source for markets where infrastructure is lagging, such as in rural Africa. “MHIET developed EBLOX as a solution to this problem, and Calik Enerji showed strong interest in the technology, offered assistance to develop EBLOX and to spread tailored solutions to Turkey, its neighboring countries, and countries in Africa,” the partners said.

According to MHIET, the first EBLOX prototype was built at Sagamihara Machinery Works in Japan in 2018. The name “EBLOX” was coined to represent the hybrid concept “between energy (E) and building blocks (BLOX),” the company said. “The name has been chosen in expectation that, with EBLOX, multiple combinations of various energy sources such as engine generators, renewable energy, and energy storage batteries can be made as if handling toy building blocks of energy sources to best suit the situation and ultimately supply the optimal power solution to each customer,” it said.

EBLOX components are coordinated by Coordy controls. “The system coordinates the different parts of Eblox to determine when, and for how long, each of the three generating functions is used,” explained MHIET Engineer Eiji Takahashi. “It performs two main functions. First, it stabilizes the solar power output. Surplus energy collected is used to recharge the battery system. In this way, the battery can provide electricity when clouds or bad weather prevent the panels from harvesting the sun’s rays, which would otherwise cause a break in supply,” he said.

Coordy’s second function is to ensure each of the three elements is optimized according to demand, he noted. “The intelligent control prioritizes solar output, then switches to battery storage, and finally utilizes the engine to provide electricity for extended periods when cleaner energy is not available.”

The hybrid solution is designed to provide reliability, the partners noted. “Renewable energy can be highly unstable due to changes in the environment and other factors, making it unreliable to power microgrids or minigrids,” they said. The stand-alone distributed power system could also be marketed to boost resiliency for power-intensive consumers. “We plan to use the demonstration to collect data for further improvement and to display EBLOX’s ability to potential customers, partners, and government authorities who are involved in constructing microgrids around Africa and neighboring countries of Turkey,” the partners said.

Courtesy: MHI